ECE 477: Digital Systems Senior Design

Functional Specification

Year: 2022 Semester: Fall Team: 16 Project: Repeat Rover

Creation Date: 08-30-22 Last Modified: 09-03-22

Team Members:

Member 1: Andres Barrera Email: barrer10@purdue.edu

Member 2: Amir Issa Email: issa9@purdue.edu

Member 3: Christine Fang Email: fang245@purdue.edu

Member 4: Waewta Saw Email: wsaw@purdue.edu

1.0 Functional Description[a]

Repeat Rover is a remote-programmable R/C vehicle designed for resource delivery in repeated process environments such as manufacturing plants and product storage warehouses. With simple manual instruction via the radio remote, the Repeat Rover will store direction and distance data in an SD card using direction collected from a magnetometer and speed from the wheel speed sensors. When prompted via a button on the bluetooth connected application, the Repeat Rover will repeat the path stored in the SD card, and then inverse the path, to repeat its steps and complete the path over again.

2.0 Theory of Operation[b]

The Repeat Rover requires the use of peripherals and sensors to measure properties in the real world. Featuring a hall effect sensor and reluctor located on the left rear wheel of the vehicle, the Repeat Rover is capable of measuring distance traversed. The Repeat Rover uses on-board bluetooth to communicate with the controller.

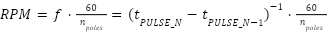

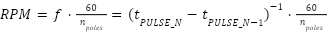

A hall effect sensor is a sensor which observes changes in magnetic field. When paired with a reluctor - a toothed ring fixed to a rotating object - a hall effect sensor is capable of measuring wheel speed and distance traversed. This is due to the poles of the ring, which activate the hall effect sensor by creating a magnetic field as they pass by the sensor. The passing of each pole induces a digital pulse signal, the frequency of which is proportional to the wheel speed of the vehicle. The following equation is used to determine wheel RPM from a hall effect digital signal:

Equation 2.1:

|

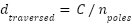

With a wheel speed sensor and a known wheel circumference, distance is easily calculated. Each revolution traverses the distance of the wheel’s circumference. Thus, the distance traversed can be calculated with Equation 2.2:

Equation 2.2:

|

Bluetooth is integrated into the Repeat Rover system in order to communicate between a mobile phone rover controller application and the vehicle. Bluetooth is a short-range communication method using radio waves at 2.402 to 2.48 GHz to wirelessly send information. Radio waves are part of the electromagnetic spectrum and travel at the speed of light. Radio waves oscillate at different frequencies. Radio antennas pick up these electromagnetic waves and convert them into electricity by vibrating electrons within the antenna. Similarly, radio transmits vibrate electrons to produce electromagnetic waves.

3.0 Expected Usage Case[c]

The Repeat Rover will be controlled by the user and is expected to be used indoors on smooth flooring. The rover is intended to be portable and can move around a room. The rover can be used by someone who has the ability to use a controller to guide the rover through space. This product is intended to be used in an automated delivery system which is capable of remembering and repeating a driven path. This product comes into good use especially when paired with an automatic item reloader at its base station or home dock that loads items to be delivered onto the car. This is carried out by a remote device which will then send a signal to the car, signaling for it to come.

4.0 Design Constraints

4.1 Computational Constraints[d]

The computational functions of our Repeat Rover are mainly focused on reading data collected from the magnetometer and the hall effect sensor (wheel speed sensor). The data will ideally be sent to the SD card for storage every 10 ms to 100 ms. Mathematical and arithmetic computations will then be performed on that set of data to compute distance and determine direction. Analog-to-digital conversion will also have to be done on the magnetometer data collected. Additionally, the speed of the motors on the remote control car will be controlled by pulse width modulation (PWM) and the direction will be determined with a H circuit.

With regards to our memory capabilities, as mentioned, most of our data collected will be stored using flash memory on the SD card. The only constraint to this is that it may be a little slower when accessing data from the SD card. It might also be subject to electronic corruption, leading to an unreadable SD card and data recovery becomes a struggle.

4.2 Electronics Constraints[e]

The major components Repeat Rover will be utilizing is a general purpose SoC, which is the nRF52832, a remote control car bought off the shelf to be repurposed to our needs, a magnetometer, a hall effect sensor (wheel speed sensor), SD card, and bluetooth low energy. The anticipated interface for these devices will be SPI, UART, or I2C. Our microcontroller will likely communicate with the IMU through I2C protocols and will receive input signals from the magnetometer and hall effect sensors. The SD card will be interfaced using SPI protocols.

The sensors, magnetometer and wheel speed sensor will need to be installed in the remote control vehicle . This means that our project will need adequate packaging on these components in order for them to perform their roles as expected. Magnetometers are very sensitive to their environment. Magnetic field distortions associated with our remote control car might occur and may cause slight disturbance to our signals. So, for useful heading and orientation computation, we need to make sure that it is calibrated to compensate for environmental noise and manufacturing defects.

4.3 Thermal/Power Constraints[f]

Repeat Rover will consist of two independent power systems. One system will power the vehicle that the microcontroller and all of its sensors are mounted onto. The second system will power the microcontroller and its peripherals, including SD storage, an accelerometer, and a magnetometer to name a few. In this system, the Repeat Rover will be utilizing the nRF52832 which requires a maximum current of 9.1mA at 3.0V. Power loss during SD card operations should be considered as an important constraint, and a power system should be added such that SD card operations can be completed before power is lost. The total heat dissipation in the microcontroller system should not exceed levels where it would be damaging to components or operators handling the device. The target battery life for this project should be such that the microcontroller system and the vehicle system have the same battery life. Ideally, this product will charge when it is not in use. This makes it essential that there is effective battery management to ensure there is no overcharging of the batteries, which will most likely be Lithium-ion batteries.

Component | Voltage | Current | Power |

Magnetometer[2] | 3.6V | 450uA | low |

Hall Effect Sensors[3] | 40V | 30mA | low |

SD card reader | 3.3V | 25MHz | 330mW |

Motor | 5V | 50A | 55mW |

Motor Driver | 36V | 2A | 2075mW |

4.4 Mechanical Constraints[g]

The Repeat Rover is a remote controlled car with our updated electronics inside the body of the vehicle. Thus, the RC car would need to be big enough to carry the pcb with the microcontroller and other electrical components, and the movement of the RC car such as turning, speeding up and stopping would not be impacted by this. However, the RC car cannot be too big to cause destruction in the area it is traversing. The packaging of the electronics must be able to prevent any wires from flying around and any electronics from being damaged. The packaging would be sealed to prevent dust and any water from getting inside.

4.5 Economic Constraints[h]

The Repeat Rover is meant to be a flexible delivery solution that can have its routes changed at a moment's notice. Repeat Rover has competitors such as Amazon's warehouse robots, and conveyor belt systems. Although Repeat Rover will not have the same computational power that Amazon's robots have, it is not meant for the same clients. Flexible delivery from workstation to workstation is important, and to stand out as a swift and changeable solution, the cost of this product should not exceed $500 in order to stay competitive with conveyor belt systems. No external products will need to be bought by the consumer for this product to work, making it a one step solution with a fixed unit price. Lastly, the lifetime of this product should be a minimum of 2 years, making the maximum cost of operation around 30 cents, assuming an 8 hour workday.

4.6 Other Constraints[i]

Other constraints would be a signal constraint for the bluetooth function of the rover. The bluetooth would connect the controller to the rover. The user would be around the distance to follow the rover around to set the initial directions. This range would be no further than a couple feet. Then when the route is set, the user can be close enough to start the path and the rover can repeat the directions on its own without the need of the bluetooth signal.

5.0 Sources Cited:

“Bluetooth”, Wikipedia,

https://en.wikipedia.org/wiki/Bluetooth (accessed 29 August 2022)

“Magnetometer”, Wikipedia,

https://en.wikipedia.org/wiki/Magnetometer (accessed 29 August 2022)

Nordic Semiconductor, “nRF52832 Product Specification v1.8”, September 2022.

https://infocenter.nordicsemi.com/pdf/nRF52832_PS_v1.8.pdf

https://engineering.purdue.edu/ece477 Page of 5

[a]Dre

[b]Dre

[c]Waewta

[d]Waewta

[e]Waewta

[f]Me

[g]me

[h]Me

[i]me